Coating and Processing

Experts In Chemical Processing

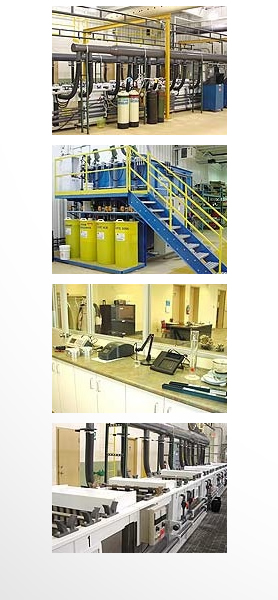

Aerosafe Processing provides Protective Chemical Finishing & Plating for Aerospace, Defence, Life Support, Satcom & Optical components. Aerosafe Processing is fully equipped with the latest state of the art Chemical Processing/Finishing equipment & Waste Water Management systems. The following processes are available:

Lab Techniques

Aerosafe Processing has a fully equipped laboratory capable of performing Chemical Analysis & Environmental testing to ensure Process Control & Process Qualification. Testing includes:

Aerosafe Processing has developed a comprehensive production flow method to ensure reliability, and repeatability of the processing procedure. This procedure ensures customers confidence in Aerosafe Processing's ability to deliver quality products, and ensure customer satisfaction. |